Automation of Processes and Logistics

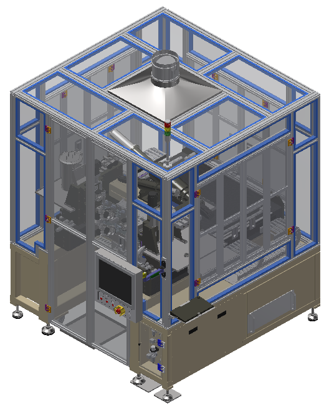

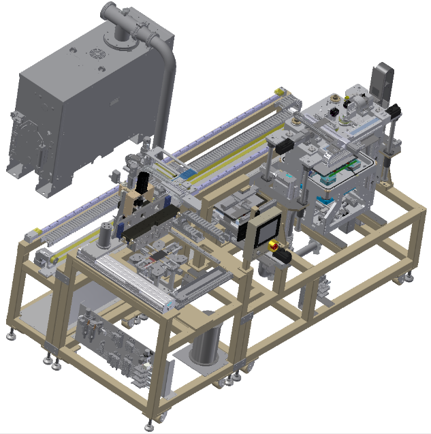

UTG(Ultra-Thin Glass) System

Specialized equipment for UTG coating processes, including articulated robot handling, USC cleaning, AP plasma treatment, vision alignment via UVW stage, precision coating, UV curing, defect inspection, and final CST loading/unloading.

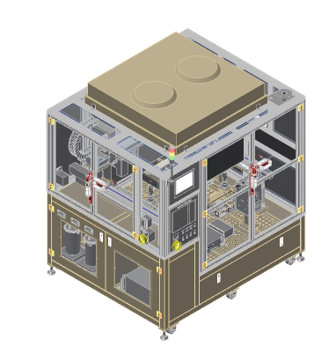

Peeler System

This equipment is used in the LCD and OLED manufacturing process to remove dust from the surfaces of CG (Cover Glass) and BA (Board Assembly), peel off protective films, and perform dry surface cleaning.

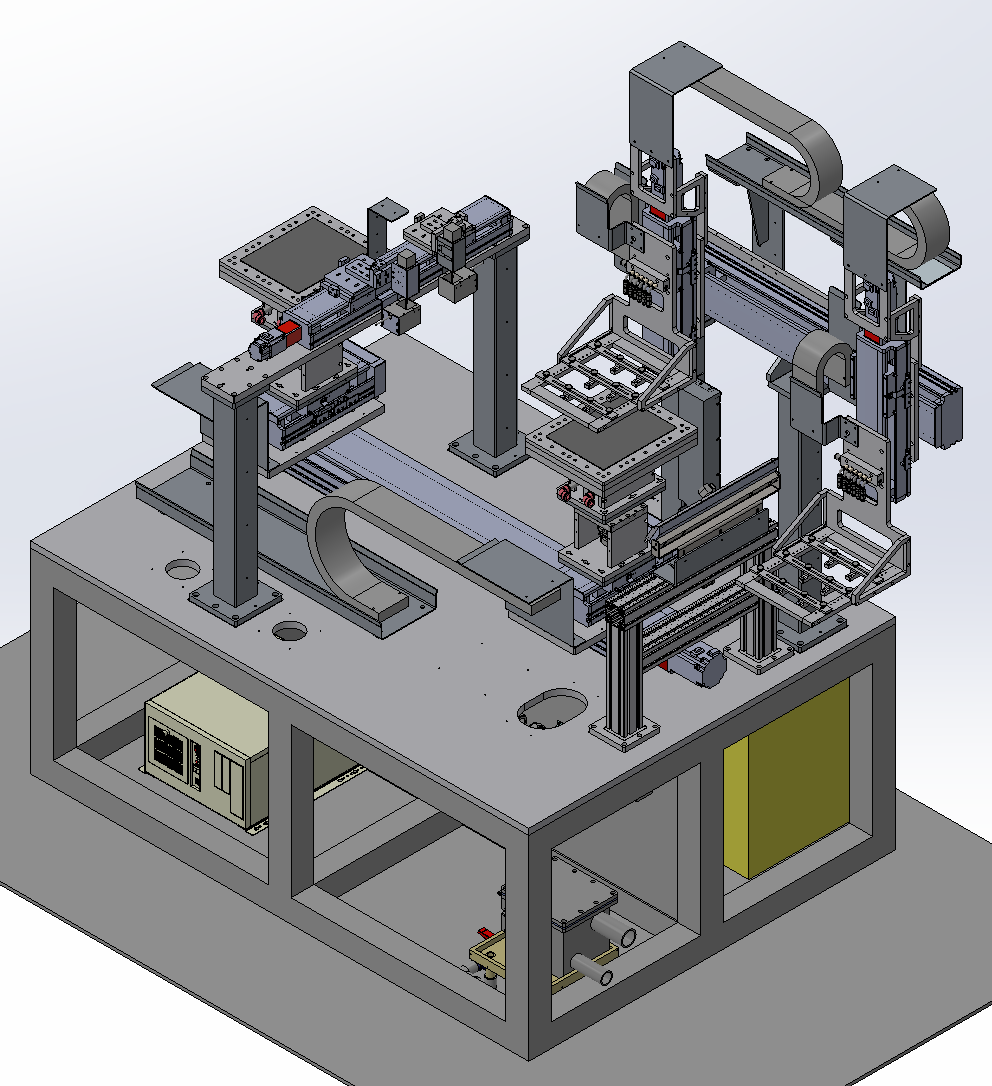

Slit Coating System

Precision Coating Equipment for Resin or PR on LCD & OLED Glass Surfaces, utilizing a Solution Pump and Slit Nozzle

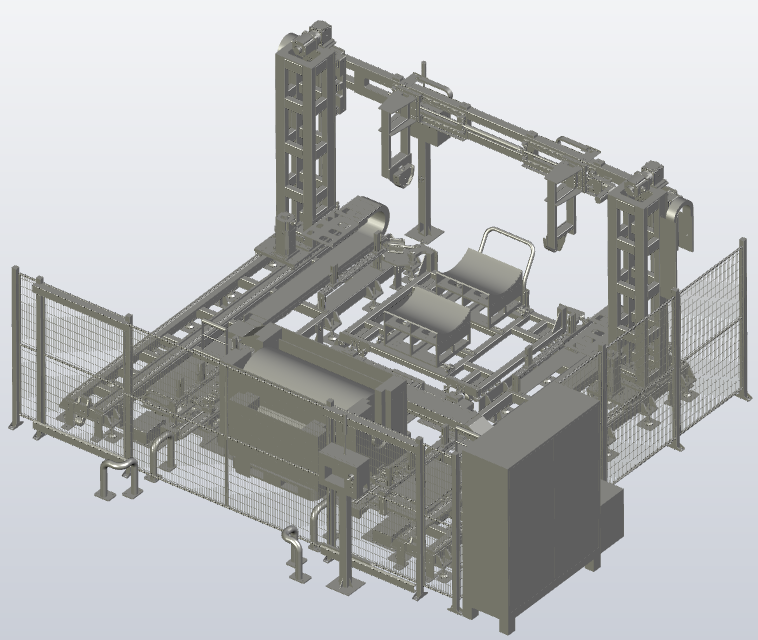

Gantry Robot Application Roll Packaging System

Heavy Roll Packing Equipment using Gantry Loader and Boxing System

Film Pick & Place System

Equipment that transports the film using a porous vacuum pad and then performs vision alignment on the UVW stage

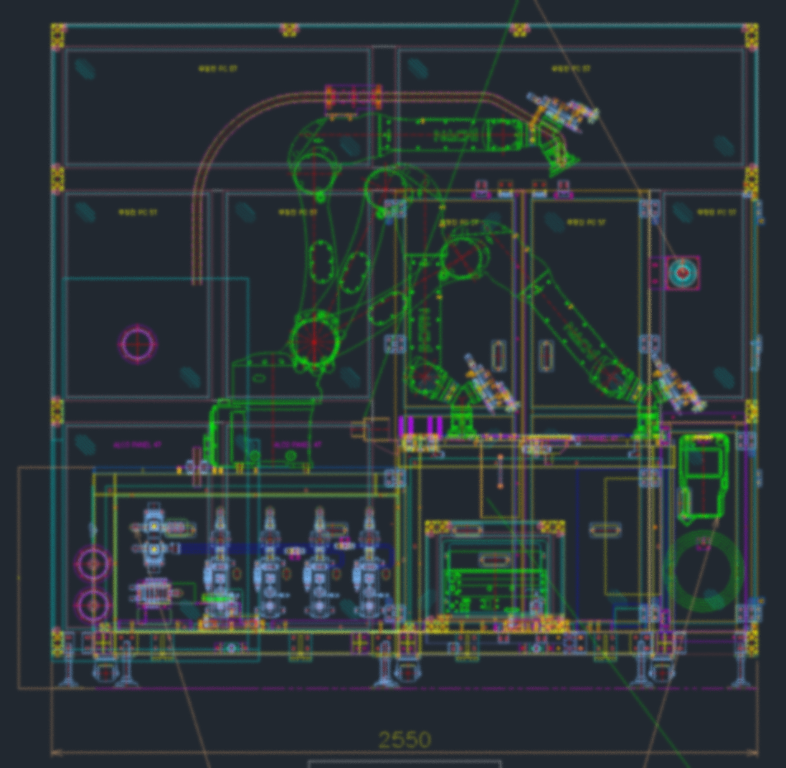

CMP Pad Buffing system

Buffing process equipment using an articulated robot for full-face polishing in CMP pad production

OCR Laminator

Display manufacturing equipment for mobile devices that precisely applies OCR on the upper surface of the cover glass to attach TSP, LCM, and BLU, and performs vacuum bonding and UV curing between units.

Dispenser MC

High-precision dispensing equipment that supplies additional resin to corner areas during the OCR coating process in Board Assy manufacturing.

Ag-Dotting MC

Equipment that jets high-viscosity AG solution between POL and TFT, and along the side of the TFT, to provide grounding for TSP during the Board Assy manufacturing process.